Tribolube 71 – O2 Compatible Lubricant Syringe (2oz)

$189.00 inc. GST

3 in stock

Tribolube 71 – O2 Compatible Lubricant Syringe (2oz)

Tribolube 71, 2 Oz. SyringeTRIBOLUBE® 71 PFPE GREASE FOR STATIC & DYNAMIC APPLICATIONS

Oxygen Safe Lubricants

With over 35 years of cutting-edge science, Aerospace Lubricants is proud to offer their latest Tribolube® line of products that is furthering the sport of scuba diving. Unlike competitive products, the Tribolube® line of products offers superior extreme pressure and anti-wear properties extending equipment life by dramatically reducing corrosion and sticky, residue buildup.

With breakthrough science and technology, Tribolube’s® revolutionary formulas make underwater breathing easy, no matter what the climate. Innovative packaging allows for a more accurate application, making Tribolube products easier to use than the competitive brands.

The Tribolube® line of O2 safe lubricants are compatible with all o-rings and materials used in the scuba industry – leading the way to safer, easier and more enjoyable scuba diving experiences.

TRIBOLUBE 71 primary characteristic is that it uses PTFE that has not been irradiated. Non-irradiated PTFE over long term exposure has demonstrated it does not corrode aluminium or anodized aluminium. Tribolube-71 has a very wide temperature range, nonreactive with strong acids, oxygen, fuels, and solvents. It is an excellent anti-wear, extreme pressure lubricant with long life. Tribolube-71 is qualified to MIL-PRF-27617 types 1, 2, & 3.

Applications

TRIBOLUBE-71 is intended for use in scuba applications as well in small and large diameter ball, roller, needle, and plain bearings, threads, valves, gears, and screw actuators. It is compatible with most elastomers and plastic seals, gaskets and O-rings. Although this lubricant is very inert, newly exposed rubbing surfaces of aluminium and magnesium may react with the greases under certain conditions.

Specifications

| Packaging | 2 Oz. Syringe |

| Tribolube Series | Tribolube 71 |

| Market | Scuba |

| Temperature Range | -100 – 450 °F |

| NLGI No. | 1 |

| Unworked Penetration @ 77°F | 294 |

| Worked Penetration @ 60 Strokes | 299 |

| Oil Separation 30 hrs @ 300°F | 9.20% |

| Oil Separation 30 hrs @ 350°F | 10.53% |

| Oil Separation 30 hrs @ 400°F | 11.7% |

| Evaporation 22 hrs @ 400°F | 0.7% |

| Evaporation 22 hrs @ 450°F | 2.88% |

| Low Temperature Torque @-65°F, Starting | 553 gm-cm |

| Low Temperature Torque @-65°F. 60 min. Running | 293 gm-cm |

| Low Temperature Torque @-75°F. Starting | 910 gm-cm |

| Low Temperature Torque @-75°F. 60 min. Running | 260 gm-cm |

| Low Temperature Torque @-100°F. Starting | 3835 gm-cm |

| Low Temperature Torque @-100°F. 60 min. Running | 1073 gm-cm |

| Copper Corrosion – 24 hrs @ 212°F | 1b |

| Load Wear Index | 144.34 |

| Last Non-Seizure @ Load/Wear Scar | None kg/mm |

| Last Seizure @ Load/Wear Scar | 620/1.87 kg/mm |

| Weld Point @ Load | 800 kg |

| Steel-on-Steel Wear @ 1200 rpm, 40 kg, 167°F, 1 hrs, 52100 steel | 1.02 mm |

| Steel-on-Steel Wear @ 1200 rpm. 40 kg. 400°F. 1 hrs. 52100 steel | 1.09 mm |

| High Temperature Performance @ 400°F, 10000 rpm, 5 lbs | +2800 hrs |

| Film Stability and Steel Corrosion 168 hrs @ 212°F | Pass |

| Water Washout- 1 hr @ 105°F | 0.1 % |

| Resistance to Aqueous Solution 168 @ 77°F | Pass |

| LOX Impact Sensitivity 20 impacts from 1100 mm | No Reaction |

| Fuel Stability @ 77°F | 0.20 % |

| Fuel Resistance 8 hrs @ 77°F | Pass |

| Oxidation Stability 100 hrs @ 212°F | -1 psi |

| Oxidation Stability 500 hrs @ 212°F | -1.5 psi |

| Mil Specs | MIL-PRF-27617 MIL-PRF-27617 (Type 1) MIL-PRF-27617 (Types 2 and 3) |

How Products are Shipped

Orders are sent via Australia Express Post, Couriers Please, Star Track and Australia Post. PO Box and Parcel Locker addresses are shipped via Australia Post; however, We cannot ship large items to these addresses, so you will need to provide a residential or business address. All smaller items and as many as possible are sent via Australia Express Post for a speedy delivery.Large Item Shipping Costs

Due to the increased freight costs, some large items incur an extra shipping fee in addition to the Flat rate shipping cost.

Large Dive Bags: $30 Long Freediving Fins: $15 Long Spearguns: $ 20 Lead Weight over 5kg: We will contact you for extra shipping costs.Shipping Time Frame

All orders are usually shipped the same day if ordered before 12 pm or 1-3 days after the initial purchase. At DGA, We only use reputable couriers that offer excellent service and fast delivery. Rural locations will take longer to arrive (non metro).Shipping Rural and Remote, Offshore islands and Territories of Australia

In rural and remote parts of Australia, shipping will depend on the availability of our shipping companies that can transport your goods to you. We always choose the fastest way possible. Please note our flat rate of $20 is based on delivery to Metro mainland Australia. Some Rural parts of Australia, Offshore islands, North Queensland, Western Australia and Territories of Australia may incur additional postage costs due to the remote location, which means our DGA Customer Service team will contact you or the extra shipping costs to get your products to you.Hassle-Free Easy 30-Day Returns Policy

We understand that the product that you have purchased may not suit or fit you. For us to best assist you in preparing for a return or exchange, please read the following information carefully before returning a product. DGA Dive Gear Australia offers you a 30-day exchange policy on most products within Australia for all goods that are unused and in a saleable condition. This means: Eligibility Conditions- The product and packaging are undamaged, unworn, unmarked and where applicable with tags still attached.

- Must include all packing material, manuals, blank warranty cards, and accessories.

- If you believe your product is faulty, please refer to the faulty items section below.

- Dive Gear Australia is not responsible for misuse of products or poor treatment of goods including proper care and servicing or equipment on time.

- Claims for missing items or items damaged in transit must be received within 7 business days of receipt of merchandise.

Returns and Exchanges

For all returns and exchanges, please contact us at sales@divegearaustralia.com.au outlining what product you would like to return, the reason and your order number. We will do our very best to look after you from there as soon as possible.Return and Exchange Shipping

Unless an item is defective, If you need to exchange or return an incorrect product, please send the item back with a copy of your invoice and any instructions or information we might need. Our customer service team will contact you as soon as we receive the goods for any charges and the cost of the return freight. Return Address: Dive Gear Australia Phone Number 0397023694Clearance and Non-returnable Items

Special order merchandise or any item indicated on the website as non-returnable is as such. Clearance items are not refundable and may not be returned unless there is a clear warranty issue or fault with the product. We will exchange as long as stock is available of the same item.Refund and Credits

Please allow up to 14 days for a credit to appear on your account from the received date. We will issue your refund in the same way you made the original purchase, minus the original cost of shipping.

Click & Collect – LOCAL PICK-UP

Shop online and then collect your order in-store with our Click & Collect service. (Melbourne and Victoria customers only).

This means you can order your favourite product online and pick it up from our store, limiting the need for physical contact with our team.

Once your order’s processed, you’ll receive a confirmation email letting you know that your order is ready for collection.

Bring your confirmation email and ID to the front of the store.

Where do I collect my order from?

Dive Gear Australia

What if I need to add or Change items that I ordered?

When picking up your order, we’ll happily assist you with any changes.

Warranty Information

From the date of purchase until the expiry of the relevant period of time specified below for the product, Aqua Lung Australia warrants that our products will be free from defects in materials and workmanship. Aqua Lung Australia’s liability under this warranty is limited to the repair, replacement or refund of the product, at the discretion of Aqua Lung Australia.

This warranty is subject to the ‘Warranty Conditions’ and compliance with the claim procedure set out below.

Warranty Conditions

Subject to the statutory guarantees that apply to goods and services purchased by Consumers (as defined in the Competition and Consumer Act 2010 (Cth)), this warranty will not include or extend to:

- defects or damages caused by improper use (including use outside of the recommended use, or use of the product beyond its designed or intended purpose, improper maintenance, neglect, unauthorised repairs, modifications, accidents, fire or casualty;

- fair wear and ageing of the product that occurs as part of its normal operation and use;

- cosmetic damage(s), such as scratches, nicks and fraying, unless the product is new and such damage is notified to Aqua Lung Australia within a reasonable time of purchase.

Consumers should refer to the owner’s manual for additional information on the correct usage and maintenance of Aqua Lung Australia products.

Duration of Warranty

Computers, Gauges and Instruments:

- 2-year limitation on warranty in relation to all Gauges and Computers used in a rental or hire.

- 1-year limitation on warranty in relation to all Accessories, consumable Parts, included but not limited to cables hoses and straps.

- 5 year limited warranty on Computers, with no limitation on the number of dives during this period. This warranty does not extend to equipment used for commercial, Military or rental purposes.

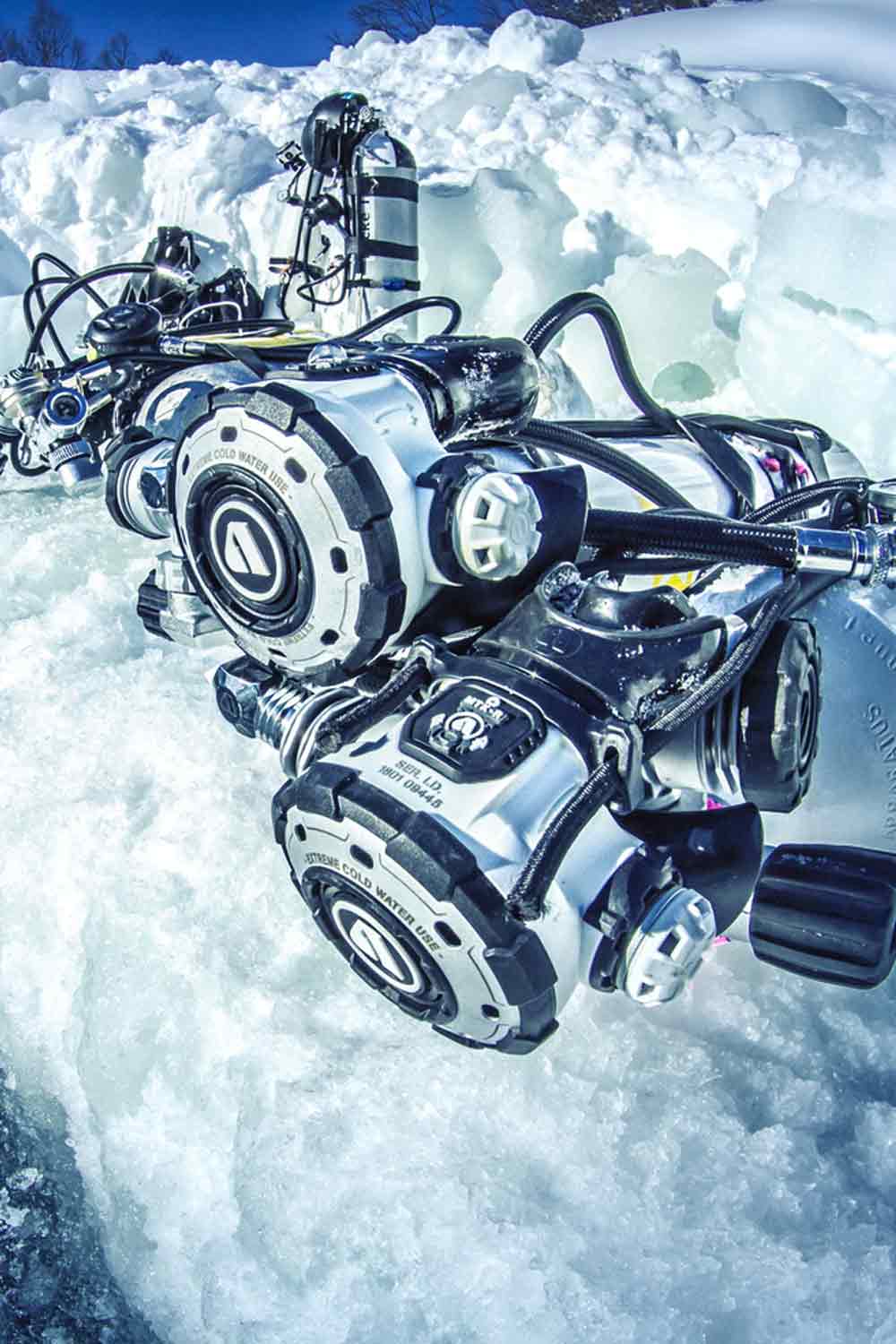

Regulators

Limited Lifetime Warranty:

No limitation on the number of dives during this period. This warranty does not extend to equipment used for commercial, Military or rental purposes.

The warranty will cover the original owner against defects in material and workmanship if the regulator is:

- Purchased from an Authorized Aqua Lung Australia Dealer

- Inspected or serviced annually by an Authorized Aqua Lung Australia Dealer.

- 1-year limitation on warranty in relation to consumable Parts.

BCD’s

Limited Lifetime Warranty:

Buoyancy Compensator Replacement on a Pro-Rated Basi

Buoyancy Compensator under the Limited Lifetime Warranty that malfunction due to material or manufacturer defects that have also had a significant amount of use will be replaced on a pro-rated basis. Prorating will be determined by a percentage factor based on the condition of the product and how long the product was used prior to the warranty claim. This can be useful to evaluate Limited Lifetime Warranty claims since the warranty period is for the “useful life of the product” and not a set length of time. The following guidelines should be used in determining what pro-rated percentage will be used.

| Pro-Rated Values for products sold at retail |

Aqua Lung Pays

|

Customer Pays

|

| Like new and less than 2 years old |

100%

|

0%

|

| Slightly used and less than 5 years old |

75%

|

25%

|

| Very used and more than 5 years old |

50%

|

50%

|

| Worn out |

0%

|

100%

|

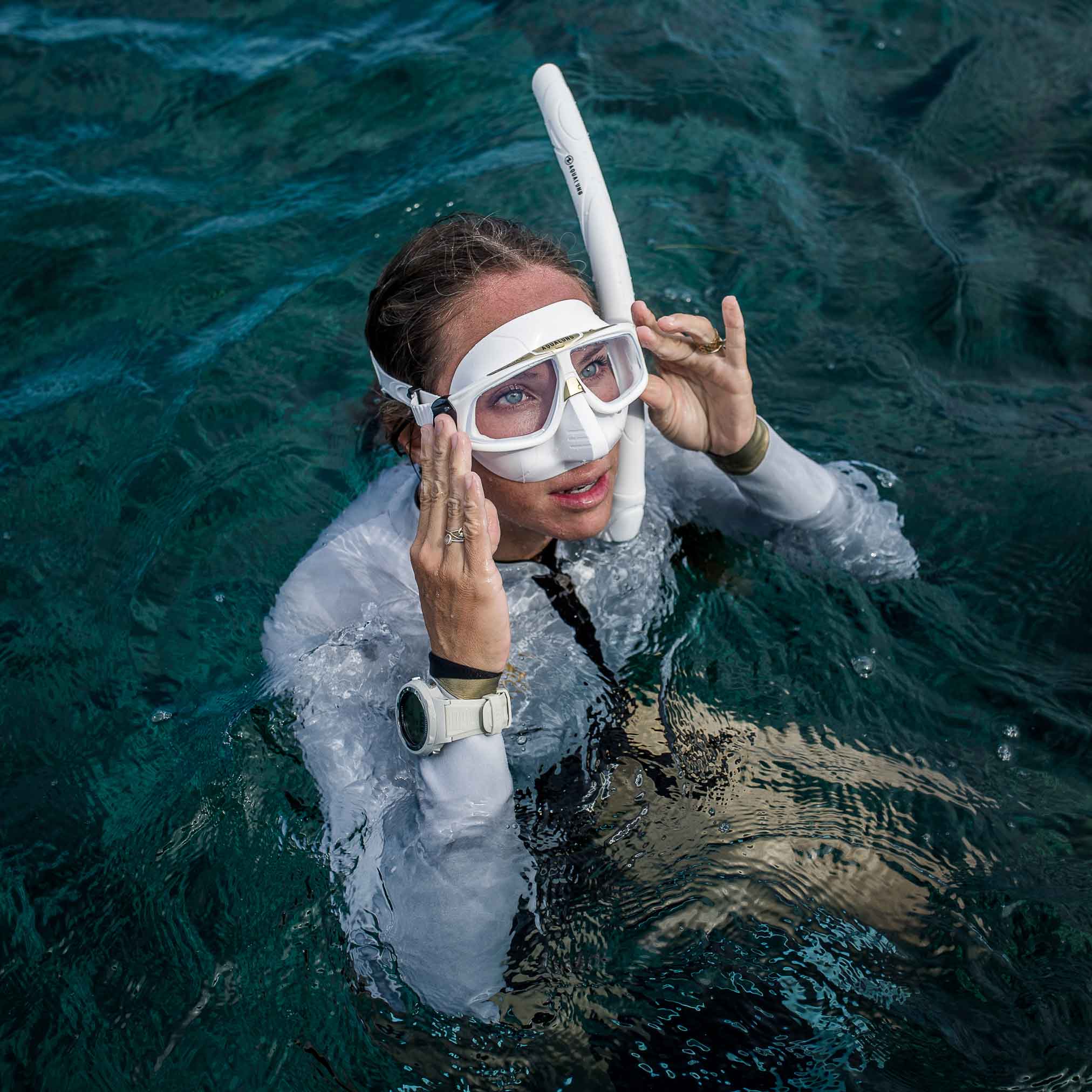

Masks, Fins and Snorkels

Two-Year Limited Warranty

Bags

Travel Bags and Explorer Series Bags: Two-Year Limited Warranty

Wetsuits

One-Year Limited Warranty

Drywear

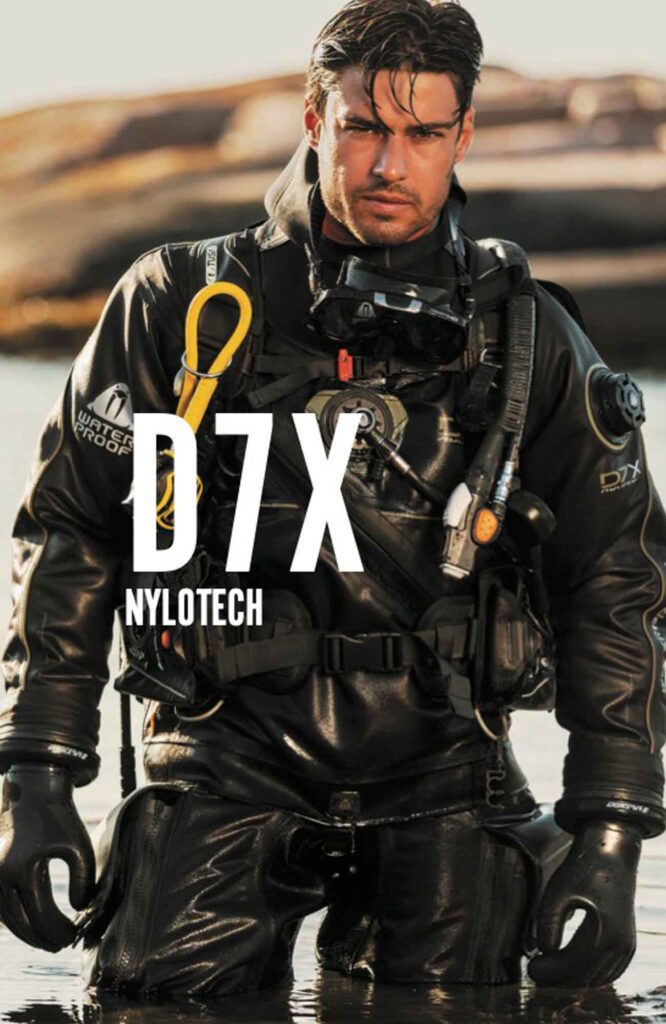

One-Year Limited Warranty

- Seams and Materials: Two-Year warranty on defects related to workmanship, materials and Seams

- Zippers and Valves: One-Year warranty from defects in materials and workmanship

- Seals: Three-Month warranty from defects in material and workmanship

Boots

One-Year Limited Warranty

Gloves:

One-Year Limited Warranty

How to make a claim

All warranty claims must be in writing and submitted to the place of purchase of the relevant product, together with details of the claim and proof of purchase as soon as the defect or damage has become apparent. You will also need to return, or make available, the product to the place of purchase for inspection.

The cost of claiming the warranty is your responsibility.

Your Rights under the Australian Consumer Law:

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.